Products

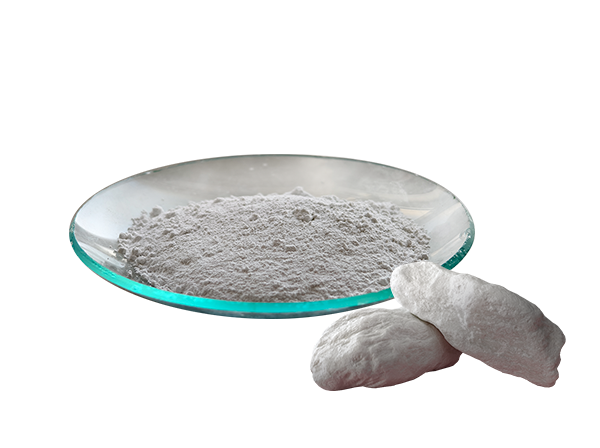

Talc Powder VT-X

Talc Powder VT-X is a natural magnesium silicate mineral powder containing water, produced through fine grinding processes. Our talc powder is characterized by high purity, excellent whiteness, stable quality, superior dispersibility, strong covering power, good oil absorption and hydrophobicity, high smoothness, low friction coefficient, and strong resistance to acid and alkali corrosion. It is widely used across various industrial fields and serves as an indispensable raw material for numerous products.

Mg3[Si4O10](OH)2

Modified Talc Powder VT-X-AS

This product is based on talc powder and undergoes surface modification and activation treatment using advanced German equipment with multifunctional surfactants and composite high-efficiency processing aids. The unique coated surface structure effectively enhances its dispersibility and compatibility in high-polymer matrices such as polyolefins. Simultaneously, it creates interfaces within the polymer matrix, further improving the impact strength of the final products. The modified talc powder can be used as a high-grade filler.

Mg3[Si4O10](OH)2

Low-Fluorine Talc Powder VT-X

Low-Fluorine Talc Powder is a powdered material produced from natural talc ore through a purification process. Its core characteristic is an extremely low fluorine element (F⁻) content (typically ≤0.01%), which is significantly lower than that of conventional talc powder (fluorine content can be as high as 0.05% or more), thereby avoiding the potential hazards of fluorides to the environment and human health.

Mg3[Si4O10](OH)2

Talc Powder for Coatings VT-X

Talc Powder for Coatings is a natural hydrated magnesium silicate mineral powder. In coatings, it primarily serves as a filler, enhancing opacity, improving adhesion, increasing hardness and wear resistance, optimizing rheology, and reducing costs. Additionally, talc powder can improve the coating's resistance to chemicals. In exterior coatings, it helps enhance weather resistance.

Mg3[Si4O10](OH)2

Magnesium Hydroxide VB-X

Magnesium Hydroxide VB-X is an ultra-fine powder produced through deep processing of the natural mineral brucite. Our company's magnesium hydroxide boasts notable features such as high purity, excellent flowability, and uniform particle size distribution. Used as a flame retardant, magnesium hydroxide possesses characteristics such as smoke suppression, smoke reduction, and non-toxicity, making it an environmentally friendly filling-type flame retardant.

Mg(OH)2

Magnesium Hydroxide for Coatings VB-X

Magnesium Hydroxide VB-X is an ultrafine powder derived from the deep processing of the natural mineral brucite. In coatings, it is primarily used as a functional additive, imparting excellent flame retardancy and corrosion resistance to the coatings. It effectively enhances the adhesion, hardness, weather resistance, and durability of the coating. Magnesium hydroxide is environmentally friendly and non-toxic, does not release harmful gases when burned, and complies with environmental standards.

Mg(OH)2

High-Purity Magnesium Hydroxide VC-X

High-Purity Magnesium Hydroxide VC-X is an inorganic compound synthesized through a chemical process, featuring extremely low impurity content, high whiteness, high purity, and excellent performance. It serves as an outstanding flame retardant for plastic and rubber products, capable of meeting the requirements of various high-end applications.

Mg(OH)2

Lightly Burnt Magnesia VK-OM

Lightly burnt magnesia VK-OM, also known as caustic magnesite or active magnesia, is produced by calcining natural magnesite ore at temperatures ranging from 700 to 1000°C. The lightly burnt ore is then physically crushed and processed into lightly burnt magnesia powder.

MgO

Active Magnesium Oxide VM-7A

Active Magnesium Oxide VM-7A is a white amorphous powder with high chemical activity and strong adsorption capacity. Characterized by fine particle size and large specific surface area, it serves as an important raw material for producing high-performance fine inorganic materials. It is soluble in acids and ammonium salt solutions, but insoluble in alcohol.

MgO

Aluminum Hydroxide VA-X

Aluminum Hydroxide VA-X is a crucial inorganic flame retardant and additive, characterized by its non-toxic, odorless, and excellent stability properties. As a flame retardant, it effectively enhances the flame resistance, heat resistance, and mechanical strength of products. Additionally, it is environmentally friendly, aligning with the development trend of green and sustainable practices.

Al(OH)3

Superfine Calcium Carbonate VC-X

Superfine Calcium Carbonate VC-X is a natural calcium carbonate ore powder. Utilizing specialized processing technology, its particle size is refined to a superfine grade without compromising its inherent structure, making it a commonly used raw material in industrial production. With abundant resource reserves, diverse performance characteristics, and a wide range of applications, it has become an indispensable key material across numerous industries.

CaCO3